Airflow and CashFlow in Paint Booths

What do we mean when we say Airflow Means Cashflow? Down draft spray booths have revolutionized the vehicle painting industry. These booths rely on precise airflow patterns to ensure a smooth, clean, and efficient paint job. But what many might not realize is that the proper functioning of these booths goes beyond just turning on a switch. From the seals on the doors to the cabin pressure to the air filters, every component plays a pivotal role in achieving a perfect finish. And a perfect finish is not just about appearance; it’s about saving time, energy, and money. Let’s delve deeper into how the various elements of a spray booth impact its performance and your bottom line.

Understanding the Role of Airflow in Spray Booths

In a down draft spray booth, airflow isn’t just an ancillary component—it’s the star player. Proper airflow ensures an even coat, prevents contamination, and speeds up the drying process.

Enveloping vs. Touching

Imagine trying to cover an object with a cloth. If you merely drape the cloth over the object, only parts of it will be covered. But if you wrap the object entirely with the cloth, every inch of it gets covered uniformly. Similarly, in a spray booth, air shouldn’t merely touch or brush up against the car section being painted. It should envelope it, ensuring that all the paint particles settle uniformly.

Common Airflow Disruptions and Their Impacts

Several factors can disturb the ideal airflow within a spray booth. Any disruption doesn’t just impact the efficiency of the process but also affects the cost and quality of the job.

Leaky Doors: A Hidden Culprit

One might not think much of a tiny whiff of air escaping from the edges of the booth doors, but these leaks can be detrimental. When doors are leaking air due to improper latching or worn-out seals, several problems arise:

- Efficiency Drop: With air escaping, the booth’s efficiency drops. It needs to work harder, consuming more energy.

- Extended Cycles: The process takes longer to complete, resulting in delayed deliveries and increased costs.

- Financial Implications: A less efficient booth means higher electricity bills and potential customer dissatisfaction from prolonged waiting times.

The Delicate Balance of Cabin Pressure

While it might seem that high cabin pressure would solve all issues, it’s not that simple. Excessively high pressure can stir up dust, dirt, and other airborne contaminants, spoiling the paint job. On the flip side, too low airflow or cabin pressure will slow down the air, leading to similar contamination problems as the airborne particles have more time to land in the paint.

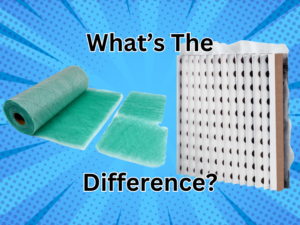

The Critical Role of Air Filters

Air filters are the unsung heroes of the spray booth world. A clogged or undersized air filter can:

- Restrict Airflow: This can result in the paint not drying properly or uniformly.

- Allow Contamination: Non-filtered air might bring in contaminants, spoiling the car’s finish.

Introducing the Solution: Proprietary Monitoring Systems

With so many factors impacting the spray booth’s efficiency, it becomes essential to have a robust monitoring system.

Real-time Insights, Anytime, Anywhere

Our proprietary monitoring system is designed to ensure your booth operates at peak performance. With monitoring points meticulously placed on critical components like exhaust, intake, burner, and more, you get a real-time live report. Whether you’re in your office or on a vacation, as long as you have computer access, you can check how your booth is performing.

Benefits of Continuous Monitoring

- Reduced Downtime: Get alerted before a component fails. Preventive maintenance can save hours of downtime.

- Quality Assurance: Ensure every paint job is of top-notch quality, reducing time spent on post-paint buffing and polishing.

- Financial Savings: Efficient operations mean reduced energy consumption, faster job completion, and satisfied customers.

Airflow = Cashflow

It’s not just a catchy phrase; it’s a reality. Ensuring optimal airflow in your spray booth directly impacts your cash flow. From saving on energy bills to reducing rework due to contamination, the benefits are manifold.

Ready for Peak Efficiency?

Contact Spray Booth Parts today. Let us install our cutting-edge monitoring system and show you the tangible difference. Remember, in the world of spray booths, proper airflow isn’t just about delivering a great paint job; it’s about ensuring profitability and business success.

The Importance of Changing Paint Booth Filters: When and Why to Replace Pre-Filters, Ceiling Intake Filters, and Exhaust Filters

The Importance of Changing Paint Booth Filters: When and Why to Replace Pre-Filters, Ceiling Intake Filters, and Exhaust Filters  Paint Booth Exhaust Filters

Paint Booth Exhaust Filters  Understanding Spray Booth Filters

Understanding Spray Booth Filters  How to Choose Spray Booth Supplies

How to Choose Spray Booth Supplies  Spray Booth Ceiling Intake Filters

Spray Booth Ceiling Intake Filters