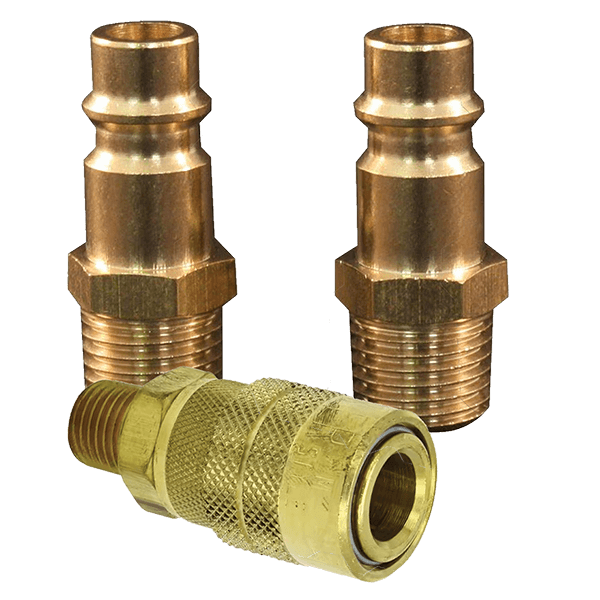

Air Hose Fittings

Air hose fittings are vital to a secure connection between air guns and compressed air sources. Air hose fittings are normally made of brass, stainless steel, or aluminum and come in various sizes and styles.

Air Hose Fittings: A Key Component for Smooth Operation

Air hose fittings are essential components that help connect hoses to spray guns, compressors, and other equipment. These fittings ensure a secure, leak-free connection and maintain optimal airflow throughout your system. Selecting the right fittings is crucial for both performance and safety.

Types of Air Hose Fittings

Quick-Connect Couplers

- These fittings allow for fast and easy hose connections, making them popular in many workshops and industrial settings.

- They are designed for quick disconnection and reconnection, saving time and effort.

Barbed Fittings

- Barbed fittings require a hose clamp to secure the hose onto the fitting. They provide a reliable connection but may require more effort to install than quick-connect couplers.

- It is best for general-purpose use where a tight, secure seal is necessary.

Threaded Fittings

- Threaded fittings offer a more permanent and secure connection. They are screwed into place, providing a durable and leak-proof seal.

- Threaded fittings can withstand higher pressures when used in more industrial or permanent installations.

Swivel Fittings

- Swivel fittings increase flexibility by reducing hose tangling. They can rotate 360 degrees, ensuring the hose moves smoothly and doesn’t get twisted during operation.

- It is ideal when the hose must be maneuvered around objects or during extended use.

Determining the Right Air Hose Fittings

When selecting the right air hose fittings, consider the following:

Material:

- Brass – A durable, corrosion-resistant material commonly used for its strength and reliability in air fittings.

- Stainless Steel – Known for its corrosion resistance, stainless steel is ideal for high-pressure applications or environments with harsh conditions.

- Aluminum – Lightweight and corrosion-resistant, aluminum is perfect for low-pressure applications.

Size Compatibility:

- Ensure the fittings match the size of the hose and the connections on your spray gun or compressor. Mismatched sizes can result in leaks or inefficiency.

Seal Quality:

- Look for fittings that include O-rings or Teflon tape to ensure a tight, leak-proof seal. This helps maintain airflow efficiency and minimizes the risk of air loss.

Maintenance Tips for Air Hose Fittings

Proper care and maintenance of your air hose fittings are key to prolonging their lifespan and ensuring smooth operation:

- Regular Inspections: Check for wear and tear, cracks, or corrosion. Replace any fittings that show signs of damage.

- Cleanliness: Keep fittings clean and free from dirt, debris, or paint residue. This will prevent clogging and improve the overall performance of your system.

- Lubrication: To maintain a smooth, easy-to-connect seal, apply a small amount of grease or oil to threaded connections.

- Check for Leaks: If you notice a drop in pressure or efficiency, check the fittings for leaks. Tighten them or replace seals if necessary.