High altitude impact on humidity levels

Colorado’s high altitude has a significant impact on humidity in spray booths. As altitude increases, air pressure decreases, leading to lower atmospheric moisture content. This results in naturally lower humidity levels compared to regions at sea level.

The reduced air pressure allows water molecules to evaporate more readily, causing drier conditions overall. Spray booth operators must be aware of this phenomenon and its implications for maintaining the ideal humidity range within their booths.

Dry climate challenges and their effect on spray booths

Colorado is known for its dry climate, characterized by low relative humidity throughout the year. This poses specific challenges for humidity in spray booths and their operations. In such arid conditions, water evaporates rapidly from paint surfaces during application, leading to faster drying times and potential issues with adhesion and finish quality.

Additionally, low humidity exacerbates overspray concerns as paint particles might dry before reaching the target surface, resulting in uneven coating distribution and wastage of materials. Spray booth operators in Colorado must employ effective humidity control strategies to mitigate these challenges and achieve optimal painting results.

Maintaining proper humidity levels is crucial in overcoming the dryness of Colorado’s climate and ensuring successful paint application within spray booths throughout the state. By understanding how high altitude affects humidity levels while also considering the challenges posed by a generally arid environment, operators can implement appropriate measures to regulate moisture content effectively within their controlled environments.

Importance of controlling humidity in spray booths

Humidity control is of utmost importance in spray booths as it directly affects the quality of paint application and drying process. Humidity refers to the amount of moisture present in the air and is usually measured as relative humidity (RH).

Maintaining appropriate humidity levels within a spray booth is crucial because it significantly impacts several aspects:

1. Paint Application: The RH level plays a vital role in achieving optimal coating results.

Too high humidity can lead to issues like blistering, bubbling, longer drying times resulting in runs or sags on painted surfaces. Conversely, low humidity can cause overspray problems due to faster drying times leading to poor adhesion and rough finishes.

2. Worker Comfort: Spray booth operators spend significant time inside these enclosed spaces. High humidity levels can make working conditions uncomfortable due to excessive heat or moisture buildup, affecting productivity and overall satisfaction.

3. Equipment Performance: Spray booths often house sensitive equipment, including air compressors, spray guns, and drying systems. Excessive humidity can negatively impact the efficiency and lifespan of this equipment, leading to potential breakdowns or reduced performance.

4. Material Preservation: Many paints and coatings are sensitive to humidity. High humidity levels can cause them to spoil or degrade faster, leading to wasted materials and increased costs.

Overall, proper humidity control in spray booths is essential for achieving consistent, high-quality finishes while ensuring the well-being of workers and prolonging the lifespan of equipment. In the unique climate conditions of Colorado, where humidity levels can vary drastically throughout the year, understanding and managing humidity is even more critical for optimal spray booth performance.

If you have any questions about how our monitoring system keeps your spray booth operating at the proper humidity, please feel free to contact us directly.

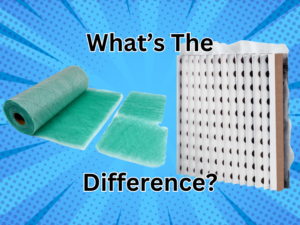

The Importance of Changing Paint Booth Filters: When and Why to Replace Pre-Filters, Ceiling Intake Filters, and Exhaust Filters

The Importance of Changing Paint Booth Filters: When and Why to Replace Pre-Filters, Ceiling Intake Filters, and Exhaust Filters  Understanding Spray Booth Filters

Understanding Spray Booth Filters  How to Choose Spray Booth Supplies

How to Choose Spray Booth Supplies  Spray Booth Regulations for Colorado

Spray Booth Regulations for Colorado  Improving Spray Booth Efficiency

Improving Spray Booth Efficiency