5 Tips to Reduce Overspray and Extend the Life of Your Filters

In any industrial or automotive painting operation, the twin challenges of overspray and filter consumption represent more than just minor inconveniences; they are significant drains on profitability and efficiency. Controlling overspray is not merely about achieving a cleaner finish—it’s a critical strategy that directly impacts material costs, equipment longevity, and operational uptime. This article covers a comprehensive, integrated system for transforming your spray booth into a high-performance, cost-effective asset.

Understanding the Impact of Overspray, Wasted Paint, and Premature Filter Failure

Overspray is the paint that misses the target part and becomes airborne, creating a cascade of negative effects. It represents wasted product, directly impacting your bottom line. This airborne paint mist is the primary culprit behind prematurely clogged exhaust filters, which restrict airflow, strain fans, and degrade the quality of subsequent paint jobs. As filters load, the booth’s environment becomes less controlled, leading to defects and rework. The scale of this issue is vast; in the automotive sector alone, illustrating a widespread operational inefficiency.

How an Integrated Approach Transforms Your Booth’s Performance

The key to significant improvement lies in understanding that spray technique, airflow management, and filter maintenance are not isolated tasks but an interconnected system. Optimizing your spray gun reduces the amount of overspray generated. Proper airflow ensures that what little overspray remains is efficiently captured. A strategic filtration plan handles this captured particulate with maximum longevity and cost-effectiveness. When these elements work in synergy, the benefits multiply, creating a cycle of continuous improvement that enhances performance, safety, and profitability.

A Practical Guide to Smarter Spraying for Enhanced Profitability

This guide provides five actionable tips that form a holistic strategy for operational excellence. We will explore how to master airflow dynamics, refine spray techniques for transfer efficiency, implement advanced filter management protocols, and integrate comprehensive maintenance schedules. By adopting these practices, you can dramatically reduce paint waste, slash filter replacement costs, and elevate the overall performance and safety of your spray booth operations.

1. The Airflow Advantage: Foundation for Efficiency and Filter Longevity

Proper airflow is the invisible force that governs the performance of your entire spray booth. It’s responsible for containing overspray, protecting the operator, ensuring a clean finish, and directing paint particulate to the exhaust filters. Without optimized airflow, even the most skilled painter with the best equipment will struggle against a poorly functioning environment.

Understanding Airflow Dynamics in Your Paint Booth

A spray booth is essentially a sophisticated air management system. Fans pull fresh, filtered air into the booth and exhaust contaminated air. The goal is to achieve a consistent, laminar flow of air that moves from the intake, across the part being painted, and into the exhaust plenum. When this flow is correct—typically around 100 feet per minute (fpm) for open-face booths—it effectively captures airborne overspray particles and carries them directly to the exhaust filters, preventing them from settling on the part or lingering in the operator’s breathing zone.

Calibrating Your Airflow: Tools and Techniques

“Checking” airflow is not enough; it must be measured and maintained. The most crucial tool for this is a manometer, which measures the static pressure difference across your filters. As filters load with dust and paint, the resistance to airflow increases, causing static pressure to rise. Your booth’s manufacturer specifies a design velocity and a maximum static pressure reading. By regularly monitoring your manometer, you can replace filters based on performance (i.e., when pressure exceeds the recommended limit), not on a generic calendar schedule. This data-driven approach ensures the booth operates at peak efficiency at all times.

Direct Impact on Overspray Control and Filter Performance

When airflow drops due to loaded filters, capture velocity decreases. Overspray is no longer efficiently pulled toward the exhaust filters. Instead, it hangs in the air, creating a fog that can settle back onto the freshly painted surface, causing defects. This lingering mist also coats the entire booth interior, including lights and walls, and eventually finds its way to the filters in a disorganized manner, leading to uneven loading and further performance degradation. Maintaining design airflow is the single most effective way to ensure overspray is managed correctly, which in turn protects your finish quality and extends the life of your filters.

2. Mastering Spray Technique

While airflow creates the right environment, the spray gun is where overspray is either minimized or created. The operator’s technique and equipment setup are paramount in achieving high transfer efficiency (TE)—the percentage of paint that successfully adheres to the target surface versus what becomes waste.

The Critical Role of Operator Training and Skill Development

Even highly experienced painters can benefit from periodic training on best practices. Key techniques include maintaining a consistent gun-to-surface distance, ensuring a perpendicular angle of application, and overlapping passes by 50-75%. Spraying too far from the part causes excessive atomization and solvent flash-off before the paint can adhere, while spraying too close can lead to runs, sags, and an uneven finish. Proper training reinforces the muscle memory needed for efficient and consistent application.

Optimizing Equipment for Minimal Waste and Superior Finish

Modern spray guns, particularly High-Volume, Low-Pressure (HVLP) models, are designed for high transfer efficiency, but only when set up correctly. This involves balancing fluid flow, atomizing air pressure, and fan pattern size. The goal is to achieve the softest possible spray that still provides a quality finish. Over-pressurizing the gun creates excessive bounce-back and airborne mist. Even a 10% increase in transfer efficiency can have dramatic effects on costs and air emissions. Dialing in your equipment for each specific product and application is a non-negotiable step in reducing overspray at its source.

Smart Application Strategies for Reduced Paint Waste

Beyond basic technique, smart strategies can further minimize waste. This includes mapping out a logical spray path before pulling the trigger, starting and stopping the spray off the part, and using the correct size spray pattern for the job. Using a wide fan pattern to paint a narrow component, for example, guarantees that a significant portion of the paint will become overspray. Adjusting the fan size to match the part being painted is a simple yet highly effective way to boost transfer efficiency and reduce material consumption.

3. Advanced Management for Cost Savings and Consistent Performance

Filters are a significant operational expense, and the market for them is substantial. The global air filters market size was valued at USD 16.00 billion in 2024, reflecting the critical role they play. Extending the life of your filters through smart management directly translates to significant cost savings and more consistent booth performance.

Understanding Your Booth’s Filtration System Architecture

Most spray booths use a multi-stage filtration system. This typically includes pre-filters or intake filters to clean incoming air, and primary exhaust filters to capture the bulk of the overspray. Some systems add secondary or final-stage exhaust filters for higher efficiency capture. Understanding how these stages work together is key. The pre-filters protect the entire system, including the painted part and the exhaust filters, from ambient dust and debris.

Implementing a Proactive Filter Maintenance Schedule

A proactive schedule is based on performance data, not the calendar. As discussed, using a manometer to track static pressure is the most reliable method. Establish a baseline reading with clean filters and log it. Then, monitor the pressure regularly. Once it reaches the manufacturer-recommended maximum, it’s time for a replacement. This approach prevents running filters past their effective lifespan, which compromises airflow and safety, and also avoids the wasteful practice of replacing them too early.

Advanced Strategies to Significantly Extend Filter Lifespan

Staged filtration is the most powerful strategy for extending the life of your expensive final filters. By using a less expensive pre-filter or a primary layer of exhaust media, you can capture the larger, heavier paint particles before they reach the main filters. This “sacrificial” first layer absorbs the brunt of the loading, allowing the finer, more costly final filters to do their job for a much longer period. This simple, cost-effective measure can often double the replacement interval for your main exhaust filters, dramatically reducing both material and labor costs.

4. Boosting Overall Efficiency: Spray Gun and Filters

A truly efficient painting operation looks beyond the immediate acts of spraying and filter replacement. It encompasses the entire workflow, energy consumption, and environmental footprint of the spray booth.

Streamlining Workflow and Booth Organization for Productivity

An organized booth is an efficient booth. Ensure that parts, tools, and supplies are staged logically to minimize downtime between jobs. The booth itself should be kept meticulously clean. Dust and debris on the floor or walls can become airborne during operation, contributing to filter loading and creating potential finish defects. A clean environment is a direct contributor to filter longevity and product quality.

Comprehensive Energy Savings and Environmental Responsibility

Clogged filters do more than just restrict airflow; they force your exhaust fan motors to work harder to maintain the required velocity, leading to a significant increase in energy consumption. By keeping filters clean and managing airflow efficiently, you reduce the load on your fans and lower your electricity bills. Furthermore, reducing overspray minimizes paint waste. This is crucial when considering that in the U.S., more than 78 million gallons of paint go unused each year, highlighting a massive opportunity for waste reduction through better application practices.

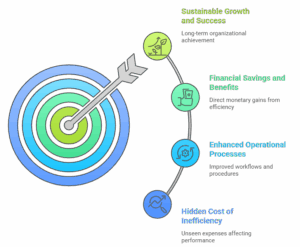

5. Quantifying Your Gains: The Tangible ROI of Smart Practices

Implementing these strategies requires an investment of time and attention, but the return on that investment is substantial, measurable, and impacts multiple areas of your business.

Calculating the Hidden Cost of Inefficiency in Your Operations

Inefficiency costs more than just wasted paint. Consider the “true cost” of a filter replacement: it includes the price of the new filter, the labor to change it, the disposal cost of the old filter, and the production downtime during the changeover. Add to this the cost of rework due to poor finishes and increased energy consumption. When you quantify these related expenses, the financial incentive to reduce overspray and extend filter life becomes overwhelmingly clear.

Demonstrating Real-World Financial Savings and Benefits

By improving transfer efficiency, you directly reduce paint consumption. A shop that reduces its paint waste can see immediate savings on material purchasing. Some studies show that between 5-12% of purchased paints are disposed of without use, a sunk cost that efficient techniques can reclaim. Doubling filter life through staged filtration and performance-based replacement can cut your annual filter budget in half while also saving on associated labor and disposal.

Case Studies and Expected Outcomes

Many industrial and automotive shops that adopt an integrated approach report significant improvements. A common outcome is a 15-20% reduction in overall paint consumption through better spray techniques alone. Coupled with smart airflow and filter management, shops often see a 50% or greater extension in the lifespan of their primary exhaust filters. These gains drop directly to the bottom line, improving profitability and making the business more competitive.

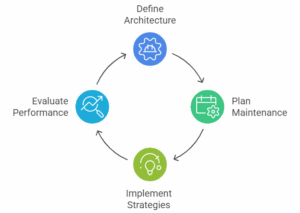

6. Integrated Maintenance and Safety Protocol

Achieving and sustaining peak performance requires a formal commitment to maintenance, safety, and continuous improvement. These elements should be integrated into a single, cohesive operational protocol.

Developing a Paint Booth Maintenance Schedule

A formal maintenance schedule should go beyond just filters. It should include regular checks and cleaning of fans, belts, motors, and ductwork. Light fixtures should be kept clean to ensure proper visibility for the painter. The booth interior should be cleaned daily or weekly, depending on usage. Documenting these tasks in a logbook ensures accountability and helps identify long-term performance trends or recurring issues.

Ensuring a Safe and Compliant Working Environment

A well-maintained spray booth is a safe spray booth. Proper airflow is essential for venting volatile organic compounds (VOCs) and protecting operators from hazardous fumes. Efficient exhaust filters are required to capture particulates and prevent their release into the environment, ensuring compliance with EPA and OSHA regulations. Performance-based maintenance ensures that your booth’s safety systems are always operating as designed.

Commitment to Continuous Improvement and Training

Technology and best practices evolve. Fostering a culture of continuous improvement is vital. This includes regular refresher training for painters on equipment and techniques, staying informed about new filter technologies, and periodically reviewing and refining your maintenance protocols. Empowering your team with knowledge and tools is the ultimate key to long-term success.

Recap of Reduced Overspray, Boosted Efficiency, and Extended Filter Life

The path to a more profitable and efficient spray booth operation does not lie in a single quick fix, but in the strategic integration of best practices. By focusing on the synergy between airflow management, spray technique, and filter maintenance, you can fundamentally shift your booth from a cost center to a high-performance profit center.

The five core strategies—mastering airflow with precise measurement, optimizing spray technique for high transfer efficiency, implementing advanced filter management, boosting overall operational efficiency, and quantifying your gains—work together to create a powerful positive feedback loop. Less overspray means filters last longer. Longer-lasting filters ensure consistent airflow. Consistent airflow enables better finish quality and a safer work environment. This integrated system reduces waste, cuts costs, and elevates the quality of your final product, delivering a sustainable competitive advantage.

How to Properly Size Your Air Compressor for Continuous Spraying

How to Properly Size Your Air Compressor for Continuous Spraying  The Role of Exhaust Filters in Protecting Your Shop and the Environment

The Role of Exhaust Filters in Protecting Your Shop and the Environment  The True Cost of Running a Paint Booth with Clogged Filters

The True Cost of Running a Paint Booth with Clogged Filters  How to Improve Shop Efficiency with the Right Paint Booth Accessories

How to Improve Shop Efficiency with the Right Paint Booth Accessories