How Filter Maintenance Saves Your Auto Shop Money

In the fast-paced environment of a commercial shop, every minute of downtime on operational costs directly impacts the bottom line. Neglecting them isn’t a minor oversight; it’s a strategic error that leads to a cascade of expensive problems. A clogged air filter is more than just dirty; it’s a bottleneck that restricts airflow, chokes equipment, and contaminates your workspace. This single point of failure can trigger higher energy bills, precipitate costly equipment repair, compromise product quality, and even impact employee health and productivity. In this article, we cleared the common misconception that filters are a trivial expense and revealed that a proactive filter-replacement strategy is one of the highest-return investments a shop can make, saving both critical time and substantial money.

Why Filters Are More Than Just a Minor Expense

In any busy shop, the focus is on throughput and output. The constant hum of machinery often drowns out the subtle signs of inefficiency. It’s easy to view filter replacement as just another line item on a long maintenance checklist—a task to be deferred when things get hectic.

Shop Filter Challenges and Misconceptions

The primary misconception is that a filter is a passive component with a single, simple job. In reality, it’s an active gatekeeper for your most critical systems. In a shop environment—be it automotive, woodworking, or manufacturing—the air is thick with contaminants far beyond typical household dust. Fine particulate from sanding, metal grinding debris, paint overspray, pollen, and other pollutants create a uniquely challenging environment.

Another common challenge is the “out of sight, out of mind” problem. Unlike a broken tool, a clogged filter’s effects are gradual. The HVAC system doesn’t fail overnight; it just works harder, consuming more energy. The air compressor doesn’t stop instantly; its performance degrades, affecting tool efficiency. Because the decline is slow, it’s often not addressed until a catastrophic failure forces the issue, leading to emergency downtime and expensive, reactive repair work.

Unlocking Quantifiable Savings

Shifting from a reactive to a proactive filter maintenance mindset unlocks a powerful financial lever. The core promise is simple: spending a small amount on regular filter replacement saves a large amount on energy consumption, equipment repair, and lost productivity. A clean filter ensures optimal airflow, the lifeblood of many systems. This allows equipment to operate at its designed energy efficiency, extends its operational lifespan, and creates a cleaner, healthier, and more productive work environment. The savings aren’t just theoretical; they are tangible, measurable, and directly contribute to a healthier bottom line.

The Tangible Costs of Neglecting Filter Maintenance in Your Shop

The true cost of a dirty filter isn’t the price of a new one; it’s the sum of all the problems it creates. These issues compound over time, turning a minor maintenance task into a major financial burden.

Skyrocketing Energy Bills and Reduced HVAC Efficiency

Your shop’s paint booth system is one of its largest energy consumers. According to the U.S. Energy Information Administration, temperature control and ventilation account for at least 35% of total energy use in commercial buildings. When an air filter becomes clogged with dust, dirt, and debris, it forces the system’s fan motor to work significantly harder to pull air through. This strain directly translates to increased electricity consumption.

This inefficiency isn’t minor. The Department of Energy estimates that regularly changing air filters can lower heating and cooling costs by 5% to 15%. For a commercial operation, this percentage represents a substantial annual saving. The principle extends beyond the HVAC and paint booth system to dust collectors and air compressors, where restricted airflow also leads to higher energy draw and inflated energy bills.

Accelerated Equipment Wear and Costly Repairs

Increased strain doesn’t just raise energy bills; it also accelerates the wear and tear on critical, expensive components. For example, in an HVAC system, restricted airflow can cause the evaporator coil to freeze over, putting immense stress on the compressor—the heart of the unit. A dirty evaporator coil can raise energy consumption by 30% or more and eventually lead to compressor failure, a repair that can cost thousands. A dirty paint booth filter will also accelerate wear and costly repairs.

Similarly, a clogged air filter in a vehicle engine forces it to run rich, leading to fouled spark plugs and potential damage to the catalytic converter. In a dust collection system, the fan motor can overheat and burn out. These are not small, incidental repairs; they are significant capital expenditures that could have been avoided with a simple, inexpensive filter replacement.

Operational Downtime and Lost Productivity

For any shop, time is money. Unexpected equipment failure means lost billable hours. If your central air compressor goes down due to a clogged intake filter, every pneumatic tool on the floor becomes useless. If the dust collection system fails, sanding and grinding operations may have to stop, creating a production bottleneck that affects multiple jobs. Similarly, a clogged paint booth filter can also cause the airflow switches in your paint booth to turn off the booth. This unscheduled downtime is far more costly than the repair itself; it represents lost revenue, delayed project deadlines, and frustrated customers. Proactive maintenance is the best insurance against these profit-killing interruptions.

Compromised Product Quality and Increased Rework

The quality of your work is your reputation. A dirty filter can directly compromise that quality. In an auto body shop, a poorly filtered paint booth can allow dust and debris to settle on a fresh coat of paint, ruining the finish and requiring hours of costly rework. In a manufacturing setting, contaminated air lines from a poorly maintained compressor can affect the performance of precision pneumatic equipment, leading to defects. A clean environment, ensured by effective filtration, is a prerequisite for high-quality output.

Health Risks and Reduced Employee Productivity

The air your team breathes directly impacts their well-being and performance. A shop environment can be filled with airborne pollutants, allergens, and fine dust particles. A well-maintained HVAC system with a clean air filter is the first line of defense, capturing these contaminants and improving indoor air quality. Poor air quality can lead to respiratory issues, allergic reactions, and general fatigue, contributing to increased absenteeism and reduced focus. A clean, healthy work environment fosters a more productive and motivated team, enhancing both the quality and speed of their work.

Direct Time Savings: Optimizing Labor and Streamlining Operations

Beyond preventing costly downtime, a structured filter management program actively saves time by making maintenance more efficient and predictable.

Reducing “Filter Flips” and Associated Labor Costs

A common but ineffective practice is attempting to clean or “flip” a disposable filter to extend its life. This is a false economy. It takes an employee’s time away from productive tasks, is rarely effective at restoring proper airflow, and can even damage the filter media, allowing more dirt to pass through. In Most cases, a paint booth filter is directional and are not able to be switched. A scheduled filter replacement takes only a few minutes, is far more effective, and ensures the system is properly protected.

Minimizing Emergency Maintenance and Unscheduled Downtime

Emergency repairs are inherently inefficient. They involve scrambling to find a technician, paying premium rates for immediate service, and waiting for parts. A proactive maintenance schedule transforms this chaos into a controlled, predictable process. Regular filter replacement is a cornerstone of this approach, drastically reducing the likelihood of sudden system failures and eliminating the time-consuming and stressful fire drill of an emergency breakdown.

Efficient Resource Allocation for Facility Managers

For shop owners and facility managers, a planned maintenance schedule allows for predictable budgeting of both time and money. You know when filters need to be changed and can allocate labor accordingly during slower periods. It allows for bulk purchasing of filters to reduce costs and ensures the necessary supplies are always on hand. This strategic approach replaces reactive problem-solving with deliberate, efficient resource management.

Strategic Filter Selection: Investing for Long-Term Shop Value

Not all filters are created equal. Choosing the right filter for each specific application is crucial for optimizing performance and achieving the best return on investment.

Understanding MERV Ratings for Optimal Shop Performance

MERV, or Minimum Efficiency Reporting Value, rates a filter’s ability to capture airborne particles. Ratings typically range from 1 to 20, with higher numbers indicating finer filtration. While a typical home might use a MERV 8 filter, a commercial shop generating significant dust might benefit from a MERV 11 or 13. A higher MERV rating captures more pollutants and smaller particles, improving indoor air quality, but it can also create more airflow resistance. It’s essential to choose the highest MERV rating your system can handle without impeding its performance, balancing air quality goals with energy efficiency. In addition, filters are rated based on efficiency. The higher the efficiency number, the less dust or paint will bypass the filter.

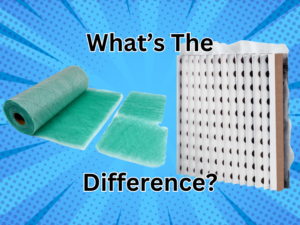

Choosing the Right Filter Type for Specific Shop Applications

The best filter type depends on the application. For Paint booths, polyester filters are the gold standard for capturing contamination but fiberglass filtersare also common for exhaust applicaitons. Dust collection systems, featuring heavy-duty bag or cartridge filters, are designed to handle high volumes of particulate matter. Vehicle engine protection, selecting an air filter that meets or exceeds OEM specifications is critical for performance and longevity.

The ROI of Higher-Quality, Longer-Lasting Filters

While it may be tempting to purchase the cheapest filter available, this is often a short-sighted decision. Higher-quality, higher-capacity filters may have a greater upfront cost but deliver a superior ROI. They last longer, reducing the frequency and labor cost of replacement. They also do a better job of protecting expensive equipment from damaging dirt and debris, which prevents costly repairs down the road. Investing in a better filter is investing in the longevity and efficiency of your critical systems.

Building a Proactive Filter Management Program for Your Business

Transitioning from a reactive to a proactive approach requires a simple but consistent system. A formal program ensures that filter maintenance is never overlooked.

Developing a Comprehensive Maintenance Schedule

The first step is to create a schedule. Audit every piece of filtered equipment in your shop—HVAC units, air compressors, dust collectors, company vehicles. Consult the manufacturer’s recommendations for filter replacement intervals and adjust based on your shop’s specific operating conditions. A dusty woodworking shop will require more frequent changes than a clean-room assembly area. Document this schedule in a logbook, a digital calendar, or a maintenance management system.

Leveraging Smart Technologies

For critical systems, consider leveraging technology. Differential pressure gauges can be installed to measure the pressure drop across a filter, providing a direct indication of how clogged it is. This data-driven approach replaces guesswork with precise, condition-based replacement triggers, ensuring you change filters at the optimal moment—not too early and not too late.

Streamlining Procurement with Filter Subscription Services

Running out of the correct filter can delay maintenance. Streamline this process by setting up a subscription service or establishing a standing order with a supplier. This ensures the right filters arrive automatically before they are needed, eliminating last-minute scrambles and keeping the maintenance schedule on track. It also helps manage inventory and can often lead to volume-based cost savings.

Empowering Your Team Through Training and Awareness

Your team is your greatest asset in maintenance. Train technicians to recognize the signs of a clogged filter, such as reduced system performance, unusual noises, or visible dirt buildup. Make filter checks a part of daily or weekly startup procedures. When your entire team understands the direct link between clean filters and equipment reliability, they become active participants in the proactive maintenance program.

Where Filter Management Makes a Difference

The principles of filter maintenance apply across various equipment, but their impact is felt differently depending on the system.

Commercial HVAC Systems

In a large commercial space, the HVAC system is responsible for employee comfort and environmental control. Clean filters ensure consistent heating and cooling, preventing productivity dips due to uncomfortable temperatures. Data from HVAC maintenance experts shows that post-cleaning HVAC systems deliver 10-46% more airflow. This improved airflow enhances efficiency, reduces energy bills, and protects sensitive electronics and machinery throughout the shop from accumulating dust.

Industrial Machinery and Dust Collection Systems

For shops involved in woodworking, metalworking, or fabrication, dust collection systems are vital for safety and air quality. A clogged filter severely reduces suction power, allowing harmful dust to linger in the air and settle on surfaces. This not only creates a hazardous breathing environment but can also pose a fire or explosion risk with combustible materials. Regular filter replacement is a non-negotiable aspect of operational safety and efficiency.

Vehicle Fleets and Automotive Service Centers

For any business with a fleet of vehicles, engine performance and fuel efficiency are direct operational costs. A clean vehicle air filter is essential for proper combustion, ensuring the engine gets the air it needs to run efficiently. The automotive filter market is a massive industry, with the global automotive air filter market valued at USD 5.8 billion in 2023, underscoring its importance. Regular replacement improves fuel economy, extends engine life, and reduces the chance of a costly roadside breakdown for your service vehicles.

Unlocking Your Shop’s Full Potential

Ultimately, viewing filter maintenance as a strategic investment rather than a mundane chore is a critical mindset shift for any successful shop owner or manager. The return on this small investment is multifaceted and significant.

Quantifiable Reductions in Operational Costs

The financial benefits are clear and direct. A proactive filter replacement program leads to verifiably lower energy bills, a dramatic reduction in emergency repair costs, and an extended operational lifespan for your most expensive equipment. It also minimizes waste from rework caused by contamination, further protecting your material costs.

Enhanced Productivity and Uptime

The greatest benefit is the optimization of your shop’s primary asset: its time. By preventing unscheduled downtime, you maximize the billable hours of both your equipment and your technicians. A reliable, efficient, and clean working environment empowers your team to perform at their best, leading to higher quality work, faster turnaround times, and greater overall profitability.

Small Filters, Big Gains: A Proactive Path to Shopwide Profitability

In the complex ecosystem of a modern shop, profitability hinges on operational efficiency. While it’s tempting to chase savings in large, obvious areas, the most significant gains often come from optimizing the small, foundational elements that support the entire operation. Filters are a prime example. They are not a passive expense to be minimized but a critical investment in the health and performance of your equipment, your employees, and your bottom line.

By moving away from a reactive, “fix-it-when-it-breaks” mentality and embracing a proactive filter management program, you can directly reduce your energy bills, avoid catastrophic equipment failures, and eliminate costly downtime. The path forward is clear:

- Audit Your Equipment: Identify every filter in your facility and document its type and recommended replacement interval.

- Create a Schedule: Develop a formal maintenance calendar and assign responsibility for filter checks and replacements.

- Optimize Your Selection: Invest in high-quality, application-appropriate filters that offer the best long-term value.

- Empower Your Team: Train your staff to be the first line of defense in identifying potential issues.

Implementing this strategy is one of the most cost-effective ways to enhance reliability, boost productivity, and unlock the full potential of your shop. Don’t let a one-percent problem cause a ninety-nine-percent headache. Invest in your filters and watch the returns multiply across your entire operation.

Top 5 Signs It’s Time to Change Your Paint Booth Filters

Top 5 Signs It’s Time to Change Your Paint Booth Filters  5 Tips to Reduce Overspray and Extend the Life of Your Filters

5 Tips to Reduce Overspray and Extend the Life of Your Filters  The Importance of Changing Paint Booth Filters: When and Why to Replace Pre-Filters, Ceiling Intake Filters, and Exhaust Filters

The Importance of Changing Paint Booth Filters: When and Why to Replace Pre-Filters, Ceiling Intake Filters, and Exhaust Filters  Understanding Spray Booth Filters

Understanding Spray Booth Filters  How to Choose Spray Booth Supplies

How to Choose Spray Booth Supplies