How Often Should You Replace Paint Booth Filters?

A paint booth is a carefully controlled space where temperature, humidity, and airflow all work together to create a flawless finish. At the heart of this control system are the paint booth filters. The optimal replacement schedule is driven by performance. Neglecting timely filter replacement compromises paint finishes, endangers workers, violates regulations, and drives up operational costs.

Understanding when and why to replace your filters is one of the most critical aspects of efficient spray booth maintenance. Optimizing filter life and performance has become a significant factor in controlling production costs and maintaining a competitive edge. We explained beyond timelines, providing a comprehensive framework for determining replacement frequency based on your specific booth type, usage, and real-world performance indicators.

The Essential Role of Replacing Paint Booth Filters

Paint booth filters are more than just consumable parts; they are essential components that directly influence every aspect of your finishing operation. A proactive replacement strategy is fundamental to achieving quality, safety, and efficiency.

Ensuring Superior Paint Finishes and Preventing Defects

The primary function of intake filters is to deliver a clean, contaminant-free bubble of air into the spray booth. When these filters become clogged with dust and debris, they can no longer do their job effectively. This allows airborne particles to enter the booth and settle on wet paint, causing defects like “fish eyes” and grit in the finish. Similarly, overloaded exhaust filters can’t efficiently remove paint overspray, causing it to swirl back onto the freshly coated surface. Poor airflow is a direct cause of defects like orange peel and sags, leading to costly rework and wasted materials.

Protecting Worker Health and Safety

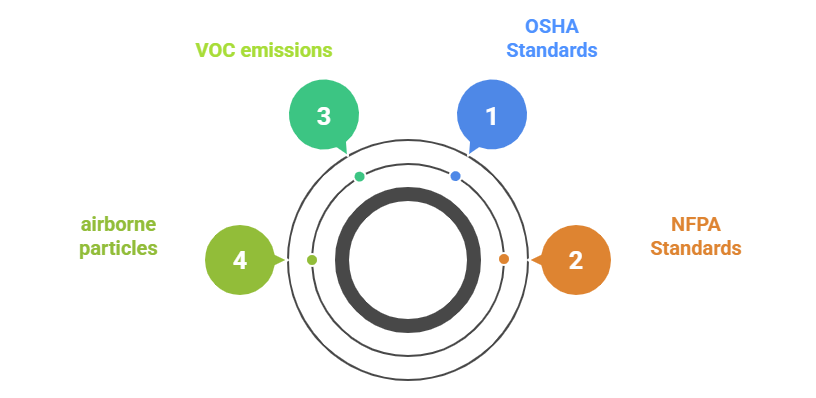

Properly functioning filters are a cornerstone of operator safety. Exhaust filters capture harmful overspray and volatile organic compounds (VOCs) from the coating, preventing them from being released into the shop environment or the atmosphere. Clogged filters restrict airflow, leading to a dangerous buildup of airborne particles and solvent vapors inside the booth. This not only creates a hazardous breathing environment but also increases the risk of fire or explosion. Regulatory bodies like OSHA and the NFPA have strict standards for ventilation and filtration in spray operations to mitigate these risks.

Optimizing Airflow and Energy Efficiency

A paint booth’s ventilation system is designed to operate within a specific range of air pressure. As filters load with contaminants, the resistance to airflow—known as pressure drop—increases. The system’s fan must work harder to pull air through the clogged filter media, leading to a significant increase in energy consumption. This strain reduces the efficiency of the entire system, leading to unbalanced airflow and inconsistent performance. A simple filter change can restore optimal airflow and dramatically reduce electricity costs.

Extending the Lifespan of Your Booth Equipment

The increased strain placed on the booth’s fan and motor by dirty filters leads to premature wear and tear. Over time, this can cause costly breakdowns and unexpected downtime. Furthermore, overspray that isn’t captured by failing exhaust filters can accumulate on the fan blades, motor, and exhaust stack, reducing their efficiency and lifespan. Regular maintenance and timely filter replacement is a small investment that protects your much larger investment in the paint booth itself.

Paint Booth’s Filtration System: Filter Types and Roles

A paint booth’s filtration system is a multi-stage process designed to clean air coming in and capture overspray going out. Understanding the role of each filter type is key to effective maintenance.

Intake/Supply Air Filters

Intake filters, also known as supply or input filters, are the first line of defense against contaminants entering the booth. Located in the Air Make-Up Unit (AMU) or ceiling, their job is to scrub the incoming air of dust, pollen, and other debris from the outside environment.

- Pre-filters: These capture larger particles and protect the more expensive, higher-efficiency filters downstream.

- Ceiling/Diffusion Media: In downdraft booths, this is the final filtration stage before air enters the cabin. This high-efficiency filter media ensures laminar airflow—a smooth, even column of air that flows over the vehicle—which is critical for preventing turbulence and achieving a flawless finish.

Universal Factors of Filter Lifespan

While booth type is a primary determinant, several universal factors affect how quickly your filters will load.

Paint Type and Volume

The type of coating being sprayed has a major impact on exhaust filter life. High-solids paints, primers, and certain industrial materials generate more overspray than standard automotive topcoats, causing filters to load faster. The volume of paint sprayed is directly correlated; the more you spray, the shorter the filter lifespan. Powder coatings have their own unique filtration requirements, often using cartridge filters designed for reclamation.

Booth Usage and Operating Hours

A high-production shop running multiple shifts per day will naturally go through filters much faster than a small auto shop that uses its booth a few times a week. Tracking operating or “spray” hours is a more reliable metric than tracking calendar days. While some general advice suggests changing filters every three weeks for a daily-use booth, according to one best practice guide, this is only a starting point that must be adjusted for actual conditions.

Environmental and Shop Conditions

The environment surrounding your paint booth plays a significant role, particularly for intake filters. A shop located in a dusty industrial area or next to a woodshop will see its intake filters load much faster than one in a cleaner environment. Some workshops in dusty conditions may require weekly checks of primary intake filters(use internal link). Keeping the area around the booth clean minimizes the amount of airborne contaminants the filtration system has to handle.

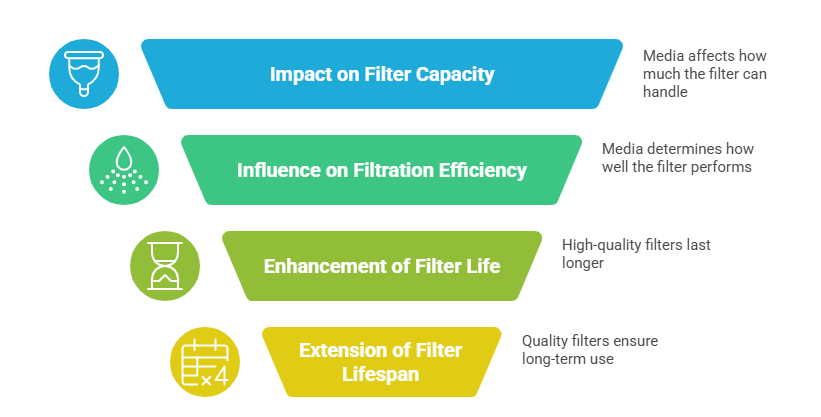

Filter Media Quality and Design

Not all filter media is created equal. High-quality filters are designed with greater dust-holding capacity and higher filtration efficiency, meaning they can capture more contaminants before airflow is significantly restricted. While they may have a higher upfront cost, premium filters often provide a longer service life and better protection, resulting in a lower total cost of ownership.

Mastering Filter Performance Monitoring: Tools and Techniques

The most effective way to manage filter replacement is to move from a calendar-based schedule to a performance-based one. This requires monitoring key indicators of filter condition.

Visual Inspections and Airflow Indicators

Regular visual inspection is a simple yet crucial maintenance task. Look for visible signs of filter clogging, such as heavy discoloration or a thick layer of dust or paint overspray. Pay attention to how the booth performs. Is overspray lingering longer than usual? Is dust appearing in your paint finishes? These are clear signs that your filters, either intake or exhaust, are no longer performing optimally and are impacting air distribution.

Establishing Baseline Readings and Trigger Points

The most accurate tool for monitoring filter condition is a manometer or a differential pressure gauge. This device measures the difference in air pressure before and after the filter bank. A clean set of filters will have a low initial pressure drop reading. As the filters capture contaminants, the pressure drop will increase. By establishing a baseline reading with new filters and knowing the manufacturer’s recommended maximum pressure drop, you can replace filters precisely when they reach the end of their effective service life—not before and not after.

Filter Replacement Frequency by Booth Type

Different paint booth designs have unique airflow patterns and filtration setups, requiring distinct maintenance schedules. The following are general guidelines; always consult your booth manufacturer’s recommendations and use a manometer for precise timing.

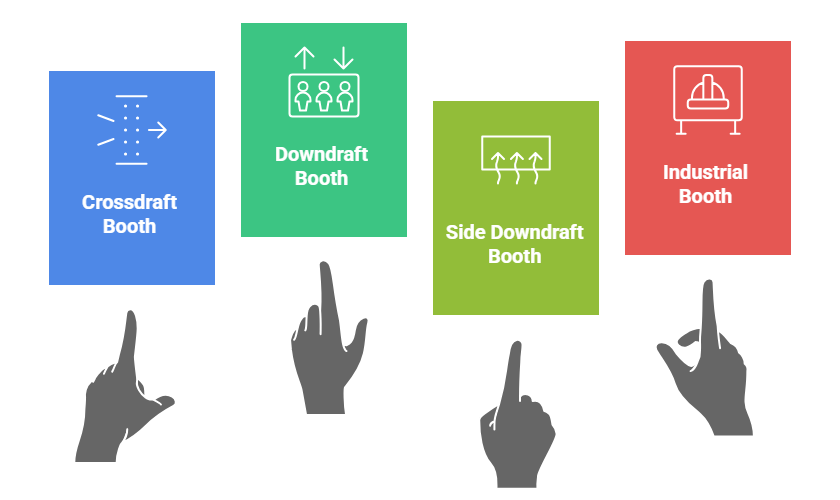

Crossdraft Paint Booths

In a crossdraft booth, air flows horizontally from intake filters in the doors, across the object, and into exhaust filters in the rear wall.

- Intake Filters: Replace every 2-4 months or 200-250 operating hours. Check more frequently in dusty environments.

- Exhaust Filters: Replace when your manometer indicates the maximum recommended pressure drop is reached, typically around 80-120 operating hours.

Downdraft Paint Booths

Downdraft booths provide the cleanest environment by pulling air from ceiling filters down into filtered exhaust pits in the floor.

- Intake Pre-filters (AMU): Replace every 1-3 months.

- Ceiling Intake/Diffusion Filters: These have a long life but are critical for finish quality. Replace every 6-12 months or 1000-1500 operating hours.

- Exhaust Filters: Replace when the manometer reaches its set point, generally every 100-150 operating hours.

Side Downdraft Paint Booths

These booths are a hybrid, with air entering through the ceiling and exiting through exhaust plenums in the lower side walls.

- Intake Pre-filters (AMU): Replace every 1-3 months.

- Ceiling Intake Filters: Replace every 6-12 months.

- Exhaust Filters: Monitor with a manometer and replace when the pressure drop limit is reached, typically around 100-150 hours.

Specialty and Industrial Paint Booths

Industrial and specialty booths (e.g., for powder coating) have highly variable schedules based on the materials being sprayed and production volume.

- Powder Coating Booths: Cartridge filters are often cleaned automatically by pulse-jet systems. Replace them only when they can no longer recover to an acceptable pressure drop after a cleaning cycle, which can be a year or more.

- High-Production Industrial Booths: These require a rigorous, data-driven maintenance schedule. Exhaust filters may need changing weekly or even daily, depending on the coating and volume.

Best Practices for Proactive Filter Maintenance

A structured approach to paint booth maintenance ensures consistency and prevents costly oversights.

Developing a Comprehensive Maintenance Schedule

Create a documented maintenance schedule and logbook. For each filter bank, record the date of the filter change, the initial manometer reading, and the operating hours. This data allows you to track trends, predict filter life accurately, and create a reliable filter schedule tailored to your specific operation.

The Importance of Proper Filter Installation

When performing a filter replacement, ensure the new filters are installed correctly. Gaps or poor seals around the filter frame will create a “filter bypass,” allowing unfiltered air or overspray to circumvent the filter media. This completely defeats the purpose of the filtration system and can lead to immediate quality defects and safety hazards.

Maintaining Booth Cleanliness and Air Make-Up Units

Filter maintenance is part of a larger booth hygiene program. Regularly clean the booth walls and floors to reduce the amount of dust that can become airborne. Periodically inspect and clean the air make-up unit, including its dampers and coils, to ensure the entire air handling plant is operating efficiently.

Training and Empowering Your Operators

Your booth operators are the first to notice changes in performance. Train them on what to look for—such as changes in airflow, lingering overspray, or finish quality issues. Empower them to read the manometer and report when filters are approaching their change-out point. Well-informed operators are crucial for effective preventative maintenance.

The Benefits of a Smart Filter Strategy

Significant Cost Savings: Energy, Rework, and Equipment Longevity

Running fans against clogged filters is a major source of wasted energy. One industry analysis highlighted that energy can cost between $3 and $40 per top-coat job, a cost that escalates with inefficient airflow. By changing filters at the right time, you minimize energy consumption, reduce the need for expensive rework, and extend the life of your booth equipment, all of which lower your overall production costs.

Enhanced Safety and Regulatory Compliance

A well-maintained filtration system is non-negotiable for compliance. The EPA, for example, has a national standard requiring shops to use exhaust filters with a minimum capture efficiency of 98% and to document their use. Proactive maintenance ensures you meet or exceed these standards, protecting your workers from hazardous materials and safeguarding your business from fines and shutdowns.

Conclusion of A Smarter Filter Replacement

Moving away from a rigid, calendar-based filter replacement schedule to a dynamic, performance-based approach is essential for any modern finishing operation. By leveraging tools like the manometer, conducting regular inspections, and understanding the specific needs of your paint booth type, you can optimize every aspect of your process. This proactive strategy is not just about maintenance; it’s about maximizing finish quality, ensuring operator safety, achieving regulatory compliance, and controlling operational costs.

To implement this strategy, begin by establishing a baseline for your clean filters and determining the manufacturer’s recommended maximum pressure drop. Create a maintenance log to track readings and operating hours, and use that data to build a predictive replacement schedule tailored to your unique conditions. A smart filter strategy is a direct investment in the quality, safety, and profitability of your work.

Different Types of Air Filter Roll Material Explained

Different Types of Air Filter Roll Material Explained  The Best Intake Filters for Flawless High-Gloss Finishes

The Best Intake Filters for Flawless High-Gloss Finishes  The Impact of Dirty Filters on Paint Jobs and Shop Productivity

The Impact of Dirty Filters on Paint Jobs and Shop Productivity  What Are Pre-Filters and Why Are They Essential in Paint Booths?

What Are Pre-Filters and Why Are They Essential in Paint Booths?  How Paint Booth Filters Help Maintain OSHA and EPA Compliance

How Paint Booth Filters Help Maintain OSHA and EPA Compliance