Maximize Your Shop Efficiency: The Essential Guide to Paint Booth Accessories

In the competitive world of automotive and industrial finishing, the pursuit of a flawless paint finish is relentless. While the spray booth itself provides the controlled environment, it’s the carefully selected ecosystem of accessories within it that truly unlocks a shop’s potential for peak efficiency, quality, and profitability. These components are not mere add-ons; they are the strategic investments that transform a good paint booth into a high-performance production powerhouse. This guide delves into the essential paint booth accessories that are critical for optimizing every stage of the finishing process, from air management to final curing.

The Efficiency Imperative in Modern Collision Repair

Today’s shops face immense pressure to increase throughput without compromising on quality. Every minute saved, every drop of paint conserved, and every rework avoided directly impacts the bottom line. Efficiency is no longer a goal; it’s a survival imperative. A well-equipped spray booth is central to this, ensuring that the finishing process is a streamlined, predictable, and profitable part of your overall workflow.

Shifting from “Add-ons” to “Strategic Investments”

Viewing paint booth accessories as simple expenses is a critical mistake. Instead, they must be seen as strategic investments in quality control, operational speed, and technician safety. An upgrade to LED lighting might prevent a single costly rework, paying for itself immediately. A superior filtration system protects expensive equipment and ensures a perfect paint finish, enhancing customer satisfaction and brand reputation. Each accessory is a tool designed to generate a tangible return.

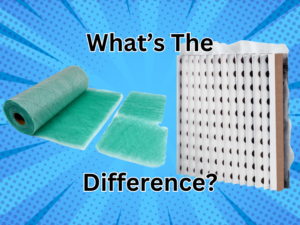

The Breathing Heart of Your Booth: Advanced Airflow & Filtration Systems

The quality of the air moving through your paint booth is the single most critical factor in achieving a pristine finish. Proper ventilation and filtration systems work in harmony to control contaminants, manage overspray, and create a safe environment for technicians.

Controlling Contaminants for a Flawless Paint Finish

Dust, debris, and oil particles are the enemies of a perfect paint job. A robust intake filtration system is the first line of defense, ensuring only clean air enters the booth. This protection is fundamental, as even microscopic contaminants can lead to blemishes that require time-consuming correction, disrupting your workflow and diminishing efficiency.

Optimizing Airflow Dynamics for Consistent Application

Consistent, non-turbulent airflow is essential for guiding paint from the spray gun to the vehicle surface and carrying away overspray effectively. Advanced airflow controls allow technicians to adjust flow rates for different materials, like modern waterborne paints, ensuring uniform application and minimizing defects. This level of control directly translates to a higher quality paint finish and reduced material waste.

Comprehensive Air Filtration for a Clean Environment

Beyond intake, a multi-stage system of exhaust filters is crucial. These filters, particularly high-efficiency exhaust filters, capture harmful overspray before it can damage the booth’s ventilation fan or be released into the environment. This protects your equipment investment, ensures regulatory compliance, and maintains the booth’s performance.

Meeting Regulatory Standards and Ensuring Safety

Proper airflow and ventilation are not just about quality; they are mandated by safety regulations like those from OSHA and the NFPA. An effective system removes volatile organic compounds (VOCs) and hazardous particulates from the technician’s breathing zone, ensuring a safe and compliant workspace.

Illuminating Perfection: The Power of Advanced Booth Lighting

You cannot correct what you cannot see. High-quality booth lighting is a non-negotiable tool for quality control, allowing technicians to identify subtle imperfections, ensure accurate color matching, and apply coatings with precision.

The Critical Role of Lighting in Quality Control

Inadequate or poorly placed lighting can hide flaws like orange peel, runs, and dust nibs until the vehicle is already outside in the sun, leading to frustrating and expensive reworks. Superior illumination turns the spray booth into an inspection chamber, empowering technicians to achieve perfection on the first attempt.

The Evolution to LED Lighting for Precision and Efficiency

The industry standard has shifted decisively to LED lighting. Unlike older fluorescent fixtures, LED lighting provides brighter, shadow-free illumination that closely mimics natural daylight, which is critical for color matching. Furthermore, LEDs are significantly more energy-efficient and have a much longer lifespan, reducing operating costs and maintenance downtime.

Strategic Placement and Uniform Illumination

Effective booth lighting depends on strategic placement. Corner-mounted vertical fixtures, combined with ceiling lights, eliminate shadows and provide consistent illumination across all vehicle panels, from rocker panels to the roof. This comprehensive coverage ensures no detail is missed during the application and inspection process.

Accelerating Throughput: Advanced Curing & Drying Technologies

The curing phase is often the biggest bottleneck in the painting workflow. Modern curing accessories are designed to drastically reduce this downtime, allowing shops to process more vehicles per day.

Revolutionizing Cycle Times with Accelerated Curing Systems

Systems utilizing short-wave infrared or advanced airflow technology can significantly shorten curing times for primers, basecoats, and clearcoats. These systems focus energy directly on the painted surface, curing from the inside out. This rapid process not only boosts throughput but can also Improve and the final paint finish by creating a harder, more durable surface.

Targeted Drying for Enhanced Efficiency

For smaller repairs, portable or targeted drying units offer immense flexibility. Technicians can cure a single panel or spot repair without having to run a full bake cycle on the entire automotive paint booth. This saves a tremendous amount of time and energy, further optimizing the shop’s workflow.

Energy Efficiency and Reduced Operating Costs

Modern curing solutions are engineered for efficiency. By reducing the duration of bake cycles and using technologies that consume less energy than traditional methods, these accessories deliver a direct reduction in utility bills, contributing positively to the shop’s profitability.

Sustaining Performance: Essential Booth Maintenance & Protection

A paint booth is a significant investment; protecting it through proactive maintenance and protective accessories is essential for ensuring its longevity and consistent performance.

Proactive Maintenance for Uninterrupted Operation

Regular maintenance schedules are vital. This includes inspecting and cleaning fans, checking door seals, and verifying that all mechanical and electrical systems are functioning correctly. Proactive upkeep prevents unexpected breakdowns that can bring production to a halt.

Keeping it Clean: Contamination Control and Surface Protection

Peelable booth coatings and floor coverings are invaluable paint booth accessories. These protective layers trap overspray and contaminants, and when they become dirty, they can be quickly peeled away to reveal a clean surface. This drastically reduces cleaning time and prevents dried overspray from flaking off and contaminating future jobs.

Optimizing Filter Changes and Service Access

A consistent schedule for filter changes is the most important maintenance task. Clogged filters restrict airflow, strain the ventilation system, and can lead to a poor paint finish. Booths designed with easy-access filter housings simplify this critical task, ensuring it is performed regularly and efficiently.

Elevating Workflow: Ergonomics, Organization & Technician Tools

Efficiency isn’t just about the equipment; it’s also about the person operating it. Accessories that improve ergonomics and organization can significantly boost technician productivity and job satisfaction.

Maximizing Technician Productivity and Comfort

Tools like man-lifts or mobile work platforms eliminate the need for ladders and awkward stretching, allowing technicians to maintain an optimal spray gun angle on all parts of a vehicle. This improves comfort, reduces fatigue, and results in a more consistent application.

Efficient Parts Handling and Staging

Dedicated parts carts and hanging racks keep freshly painted components organized, safe from damage, and out of the way. An efficient staging process outside the booth streamlines workflow, reducing turnaround time and minimizing booth idle periods between jobs.

Organized Workspace, Optimized Results

A well-organized workspace reduces wasted time searching for tools and materials. Integrated mixing rooms, spray gun holders, and hose management systems keep the environment clean and orderly, allowing technicians to focus solely on their craft.

Enhancing the Work Environment for Improve Shop Efficiency

Simple additions like improved door seals can reduce noise levels, creating a more pleasant work environment. A comfortable and well-equipped technician is a more focused and productive employee, directly contributing to the shop’s success.

Safety and Compliance: Protecting Your Investment and Your Team

Beyond performance, a range of accessories is ensuring the safety of your personnel and compliance with industry standards.

Adhering to Industry Safety Standards

Safety features like airflow monitoring systems, fire suppression systems, and proper emergency stops are not optional. They are required components that ensure your automotive paint booth operates within established safety protocols, protecting your staff and your business from liability.

Complementing Personal Protective Equipment (PPE)

While PPE is the technician’s personal defense, booth accessories can enhance safety. An airline breathing system integrated into the booth supplies clean air, complementing the technician’s respirator for reliable, maximum protection.

Ensuring a Safe and Clean Operating Environment

A clean, well-maintained booth is inherently a safer one. Protective floor coverings can reduce the risk of slips, while effective overspray capture by exhaust filters improves air quality both inside and outside the booth, ensuring a responsible and safe operation.

Elevate Your Shop’s Potential with Smart Accessory Choices

Maximizing your shop’s efficiency goes far beyond the basic structure of your paint booth. It requires building a complete ecosystem of strategic paint booth accessories that work together to enhance quality, accelerate throughput, and ensure safety. By shifting your perspective from “add-ons” to “investments,” you can systematically upgrade your capabilities in airflow management, lighting, curing, and workflow.

The path to greater profitability lies in a holistic approach. Begin by auditing your current spray booth setup. Identify bottlenecks, assess lighting quality, and review your maintenance and filter changes protocol. Investing in the right accessories—from high-efficiency exhaust filters and LED lighting to accelerated curing systems and ergonomic tools—will deliver a powerful return, reducing rework, conserving materials, and ultimately driving your business forward.

How Regular Filter Changes Save Your Shop Time and Money

How Regular Filter Changes Save Your Shop Time and Money  Top 5 Signs It’s Time to Change Your Paint Booth Filters

Top 5 Signs It’s Time to Change Your Paint Booth Filters  5 Tips to Reduce Overspray and Extend the Life of Your Filters

5 Tips to Reduce Overspray and Extend the Life of Your Filters  The Importance of Changing Paint Booth Filters: When and Why to Replace Pre-Filters, Ceiling Intake Filters, and Exhaust Filters

The Importance of Changing Paint Booth Filters: When and Why to Replace Pre-Filters, Ceiling Intake Filters, and Exhaust Filters  Understanding Spray Booth Filters

Understanding Spray Booth Filters