Sia Abrasives 1950 Siaspeed Sanding Discs

The 1950 Siaspeed 6″ Sanding Disc is specifically engineered for high-performance surface preparation across the most demanding applications. Leveraging advanced ceramic grit technology in the coarse range (P40-P80) for aggressive material removal, and premium aluminum oxide for finer grits, the 1950 siaspeed delivers superior stock removal and consistent, high-quality finishes. This robust construction ensures extended lifespan and makes it the top choice for professionals in automotive refinishing, woodworking, and industrial metalworking. Invest in efficiency and quality that lasts.

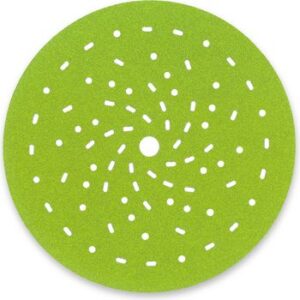

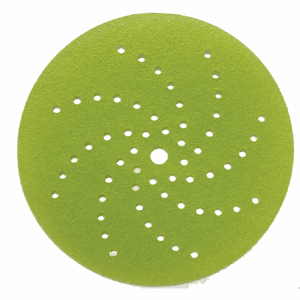

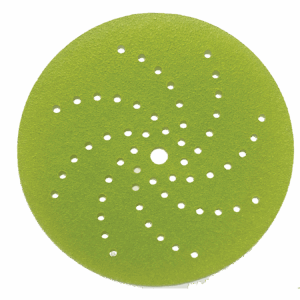

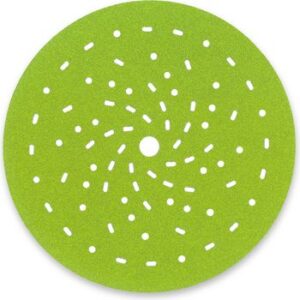

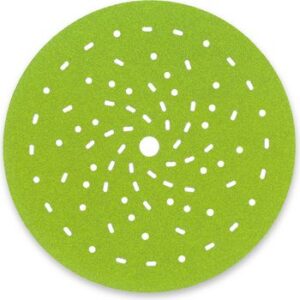

Maximum Efficiency Through Multi-Hole Dust Extraction

Designed to maximize productivity, the 1950 siaspeed features an optimized multi-hole pattern for highly efficient dust extraction. This system dramatically improves work efficiency by keeping the sanding surface clean, reducing heat build-up, and preventing premature clogging. The result is fast results with less effort, reducing downtime and creating a cleaner, safer working environment. Whether flatting body filler or keying lacquers, the superior dust control ensures the disc performs optimally and maintains its cutting edge throughout the entire process.

Versatile Solution for Flawless Automotive & Industrial Finishes

The 1950 siaspeed disc offers unmatched versatility, handling a broad spectrum of materials and applications from coarse to ultra-fine sanding. It is ideal for sanding out unevenness, flatting body filler, fine sanding of primer filler, and the crucial preparation for high-gloss polishing. Effective on Color, Lacquer, GRP, Plastics, and various Primer types, its specialized stearate coating from P80 onwards further prevents clogging, ensuring continuous and smooth operation. The 1950 siaspeed is the reliable, professional-grade solution for achieving a flawless finish on virtually any surface.

Application:

- Sanding of coatings and impurities

- Sanding out unevenness at the edges of repaired surfaces

- Flatting of body filler and composite materials

- Fine sanding of primer filler

- Keying of old and new lacquers

- Producing a matt finish on old and new lacquers for blending

- Removal of orange peel effect and dust inclusions

- Preparation for polishing on high-gloss surfaces

Use for:

- Color

- Primer filler

- Body filler

- Lacquer

- Old lacquer

- Primer coat

- Epoxy primer coat

- Cathodic dip primer coat

- Plastics

- Acrylic glass

- Gelcoat polyester

- Glass-fiber reinforced plastic (GRP)

Profile

Grit type:

Mixed grit with ceramic content – 40 – 80

Semi-friable aluminum oxide / blue-fired – P100 – P400

White aluminium oxide – P500 – 1500

Backing:

Paper (FSC-certified) – 40 – 600

Film – 800 – 1500

Coating:

Electrostatic – 40 – 180

Electrostatic open – 220 – 600

Special process – 800 – 1500

Bonding:

Resin over resin

Special coating:

Stearate – from 80