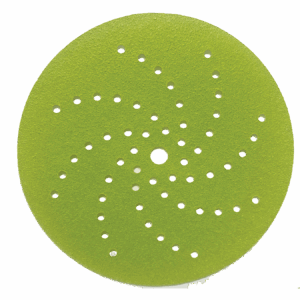

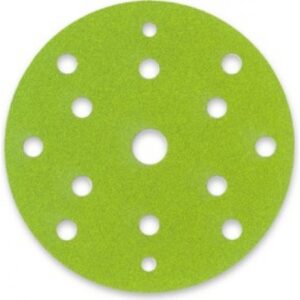

High-Efficiency Stock Removal: 1950 Siaspeed 6″ Adhesive Back Discs

The sia Abrasives 1950 Siaspeed 6″ Sanding Disc is engineered for high-performance stock removal and reliable surface leveling. Utilizing a durable, FSC-certified paper backing and semi-friable aluminum oxide grit, this 120 GRIT abrasive delivers superior, fast material removal and a uniform scratch pattern. It is the top choice for professionals in automotive refinishing, woodworking, and industrial metalworking who rely on its strong Adhesive Back attachment. The multi-hole pattern ensures efficient dust extraction, improving work efficiency and contributing to a cleaner, safer environment.

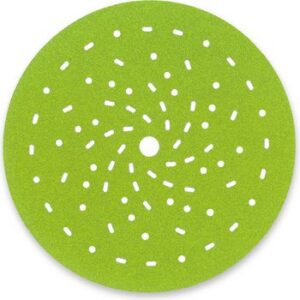

Optimized for Filler, Primer, and Coating Removal

This 120 GRIT 1950 Siaspeed disc is optimized for aggressive intermediate tasks, including flatting of body filler and composite materials, sanding out unevenness at repaired edges, and the rapid removal of old coatings and impurities. The robust paper backing provides a reliable base, while the electrostatic coating helps minimize clogging, maximizing the disc’s lifespan on various challenging materials. This controlled sanding ensures a highly effective and uniform base for subsequent, finer-grit refinement, reducing downtime and boosting productivity.

Versatile Abrasive for Initial Surface Preparation

From preparing gelcoat polyester and GRP to keying old lacquers and primer coats, the 1950 Siaspeed 6″ sanding disc delivers consistent, professional-grade results across a wide range of applications. Its durable grit and special Stearate coating ensure high clog resistance and excellent performance. The combination of its superior stock removal capability and the convenience of the adhesive backing makes this disc an essential and economical solution for achieving a uniformly keyed and leveled surface ready for further finishing.

Application:

- Sanding of coatings and impurities

- Sanding out unevenness at the edges of repaired surfaces

- Flatting of body filler and composite materials

- Fine sanding of primer filler

- Keying of old and new lacquers

- Producing a matt finish on old and new lacquers for blending

- Removal of orange peel effect and dust inclusions

- Preparation for polishing on high-gloss surfaces

Use for:

- Color

- Primer filler

- Body filler

- Lacquer

- Old lacquer

- Primer coat

- Epoxy primer coat

- Cathodic dip primer coat

- Plastics

- Acrylic glass

- Gelcoat polyester

- Glass-fiber reinforced plastic (GRP)

Profile

Grit type:

Mixed grit with ceramic content – 40 – 80

Semi-friable aluminum oxide / blue-fired – P100 – P400

White aluminium oxide – P500 – 1500

Backing:

Paper (FSC-certified) – 40 – 600

Film – 800 – 1500

Coating:

Electrostatic – 40 – 180

Electrostatic open – 220 – 600

Special process – 800 – 1500

Bonding:

Resin over resin

Special coating:

Stearate – from 80