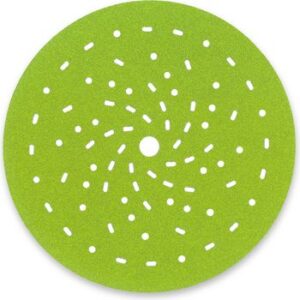

SiaSpeed 1950 5-Inch Sanding Discs: High-Performance 60 Grit Stock Removal

Experience Maximum Cutting Power with SiaSpeed 1950 Technology

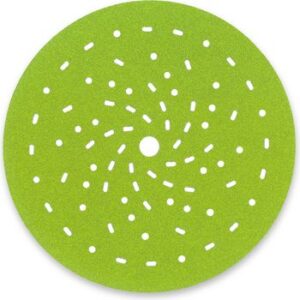

The 1950 SiaSpeed 5″ Sanding Disc in 60 grit is a high-performance abrasive engineered for rapid material removal and aggressive surface leveling. Designed for professionals who need to cut through tough coatings, fillers, and raw wood quickly, the SiaSpeed line provides a unique abrasive structure that combines an exceptionally high initial cut with a long-lasting service life. The 0-hole (solid) design ensures 100% surface contact, delivering maximum abrasive power to every square inch of your workpiece.

Industrial Grade Durability with Advanced Anti-Clogging

Built to handle the heat and pressure of heavy-duty sanding, the SiaSpeed 1950 series features a specialized stearate coating that significantly reduces loading and pilling. This technology keeps the 60 grit grains sharp, even when stripping “sticky” materials like fiberglass, plastics, or thick automotive primers. The secure Hook & Loop backing system allows for rapid disc changes on any 5-inch orbital sander, ensuring a firm grip and stable, vibration-free performance during intense stock removal tasks.

Application:

- Sanding of coatings and impurities

- Sanding out unevenness at the edges of repaired surfaces

- Flatting of body filler and composite materials

- Fine sanding of primer filler

- Keying of old and new lacquers

- Producing a matt finish on old and new lacquers for blending

- Removal of orange peel effect and dust inclusions

- Preparation for polishing on high-gloss surfaces

Use for:

- Color

- Primer filler

- Body filler

- Lacquer

- Old lacquer

- Primer coat

- Epoxy primer coat

- Cathodic dip primer coat

- Plastics

- Acrylic glass

- Gelcoat polyester

- Glass-fiber reinforced plastic (GRP)

Profile

Grit type:

Mixed grit with ceramic content – 40 – 80

Semi-friable aluminum oxide / blue-fired – P100 – P400

White aluminium oxide – P500 – 1500

Backing:

Paper (FSC-certified) – 40 – 600

Film – 800 – 1500

Coating:

Electrostatic – 40 – 180

Electrostatic open – 220 – 600

Special process – 800 – 1500

Bonding:

Resin over resin

Special coating:

Stearate – from 80