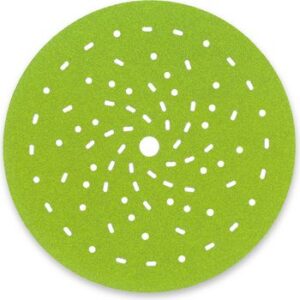

SiaSpeed 1950 5-Inch Sanding Discs: High-Performance 320 Grit Ultra-Fine Finish

Achieve a Flawless Surface with SiaSpeed 1950 Speed-Tech

The 1950 SiaSpeed 5″ Sanding Disc in 320 grit is a premier abrasive designed for professionals who demand an ultra-fine finish in record time. This grit is specifically engineered for final preparation stages, such as sanding between coats of varnish, scuffing clear coats, and refining high-quality primers. The SiaSpeed technology provides a high initial cutting power that stays consistent, ensuring that your 125mm orbital sander produces a perfectly uniform texture across delicate automotive, marine, and woodworking surfaces.

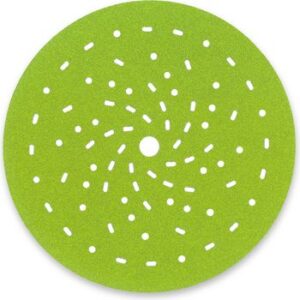

Innovative Anti-Clogging Technology for Industrial Refining

Crafted for high-production environments, the SiaSpeed 1950 series features a specialized stearate coating that prevents dust loading and heat friction. This ensures that the 320 grit grains remain sharp and effective, providing a consistent finish without the risk of “pilling” or burning the surface. The premium Hook & Loop backing offers a secure, centered attachment for balanced, vibration-free sanding, while the 100-pack box provides exceptional value for shops requiring a high volume of finishing discs.

Application:

- Sanding of coatings and impurities

- Sanding out unevenness at the edges of repaired surfaces

- Flatting of body filler and composite materials

- Fine sanding of primer filler

- Keying of old and new lacquers

- Producing a matt finish on old and new lacquers for blending

- Removal of orange peel effect and dust inclusions

- Preparation for polishing on high-gloss surfaces

Use for:

- Color

- Primer filler

- Body filler

- Lacquer

- Old lacquer

- Primer coat

- Epoxy primer coat

- Cathodic dip primer coat

- Plastics

- Acrylic glass

- Gelcoat polyester

- Glass-fiber reinforced plastic (GRP)

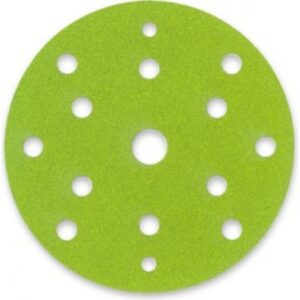

Profile

Grit type:

Mixed grit with ceramic content – 40 – 80

Semi-friable aluminum oxide / blue-fired – P100 – P400

White aluminium oxide – P500 – 1500

Backing:

Paper (FSC-certified) – 40 – 600

Film – 800 – 1500

Coating:

Electrostatic – 40 – 180

Electrostatic open – 220 – 600

Special process – 800 – 1500

Bonding:

Resin over resin

Special coating:

Stearate – from 80