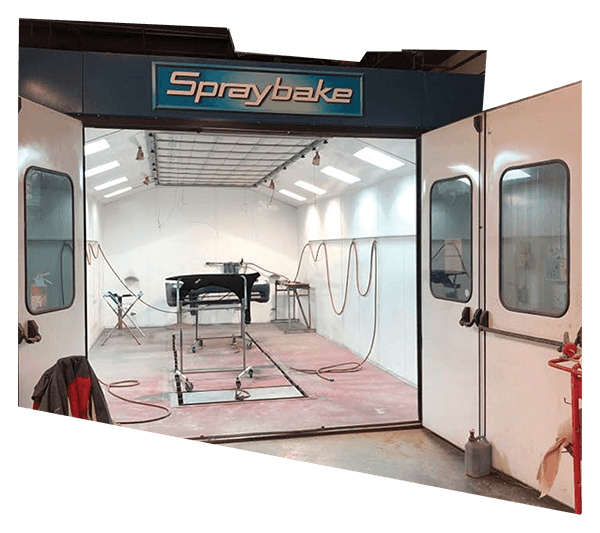

Spraybake

Spraybake paint booths were originally manufactured in England and Canada but are no longer available. Many Spraybake booths are still in use today. We offer all paint booth filters for Spraybake including intake and exhaust.

Spraybake Paint Booth Filters

Though Spraybake paint booths are no longer manufactured, many still operate today. Initially produced in England and Canada, these booths require regular filter maintenance to ensure clean airflow and optimal painting conditions.

Types of Spraybake Filters

Air Intake Filters

Spraybake intake filters help prevent airborne dust and contaminants from entering the booth. They are designed to maintain a steady, clean airflow, ensuring high-quality paint finishes.

Exhaust Filters

Spraybake exhaust filters capture overspray and help maintain airflow while complying with environmental regulations. Available options include:

- Fiberglass Pads: Cost-effective and commonly used in Spray bake booths for filtering paint overspray.

- Polyester Media Rolls: Provide higher filtration efficiency and longer-lasting performance.

- Cardboard Baffle Filters: Designed for high-capacity overspray collection, extending filter life.

Ensuring Optimal Performance

Since Spray bake booths are no longer in production, using the right replacement filters is essential to keep them running smoothly. Regular filter changes help:

- Maintain clean air inside the booth for better paint quality.

- Prevent contamination and defects in finished work.

- Extend the lifespan of booth components and reduce maintenance costs.

Showing all 4 results

-

Paint Booth Ceiling Intake Filter Blanket 39″ x 292″ – QTY: 1

$170.24 Add to cart -

Paint Booth Ceiling Intake Filter Blanket 60″ x 342″ – QTY: 1

$306.74 Add to cart -

Paint Booth Ceiling Intake Filter Blanket 60″ x 312″ – QTY: 1

$279.83 Add to cart -

Paint Booth Ceiling Intake Spraybake Filter Blanket 78.75″ x 246″

$289.92 Add to cart

Choosing the Correct Replacement Filters for Spraybake Models

Since original equipment manufacturer (OEM) parts for Spraybake are scarce, selecting the right aftermarket filters is critical. When sourcing replacements, it is essential to measure your current filter grid accurately, as Spraybake models varied in size depending on whether they were manufactured in England or Canada. Ensure you check the diffusion ceiling filter density to match the specific airflow requirements of your booth model. Using filters with the correct MERV rating ensures that your older unit continues to operate within the manufacturer’s original pressure specifications.

Signs It Is Time to Replace Your Booth Filters

To keep a legacy Spraybake booth running efficiently, operators must monitor filter saturation closely. While a visual inspection is helpful, relying on a manometer (draft gauge) is the most accurate method. If the pressure differential exceeds the recommended limit, airflow becomes restricted, leading to negative pressure issues. Common signs that your intake or exhaust filters need immediate replacement include:

-

Hazy overspray lingering in the booth longer than usual.

-

Dust nibs or particles appearing in the clear coat.

-

Decreased air velocity during the spray cycle.

Why High-Efficiency Media Matters for Older Booths

Older Spraybake units rely heavily on proper airflow balance to cure paint effectively. Upgrading to high-efficiency media, such as tacky intake filters or high-holding capacity fiberglass exhaust rolls, can compensate for the wear and tear on older fans and motors. High-quality media captures smaller micron particles that cheaper alternatives miss, protecting the booth’s mechanical components from overspray buildup and ensuring that the exhaust air meets current EPA and local environmental safety standards.