Compressor Filters

Compressors have many moving parts to create reliable compressed air. Specialty compressor equipment uses many different types of filters depending on the manufacturer and model of the equipment. Compressors require air filters and oil filters in order to work properly and they must be changed regularly.

When do I change compressor filters?

Depending on the make and model of the air compressor, filters should be changed based off of how many hours the unit has run and the unit age.

Compressor Filter: Essential for Reliable Airflow

Compressor Filters rely on many moving parts to generate and maintain consistent compressed air. To ensure optimal performance, specialized compressor filter remove contaminants, protect internal components, and extend equipment lifespans.

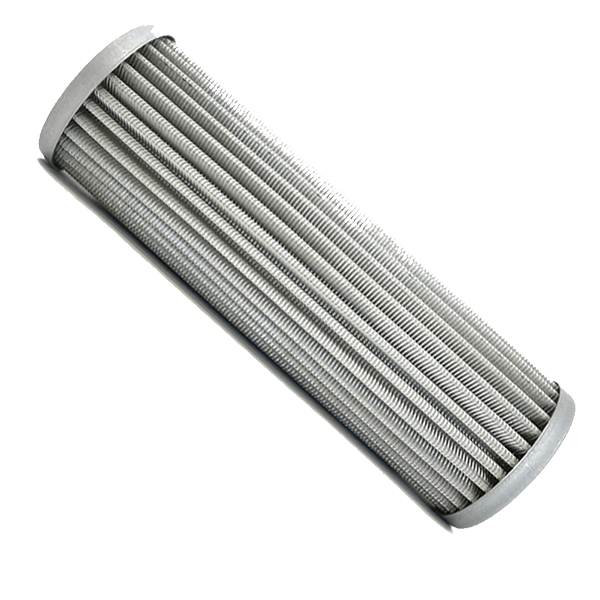

Types of Compressor Filter

Different air compressor models require specific filters based on their design and function. The two primary types include:

- Air Filters: Prevent dust, dirt, and debris from entering the compressor, protecting internal components.

- Oil Filters: Remove contaminants from the lubrication system to keep the compressor running smoothly.

When to Change Compressor Filter

The replacement schedule for compressor filter depends on several factors, including the make and model of the equipment. Filters should be changed based on:

- Operating Hours: Most manufacturers recommend filter replacement after a specific number of hours.

- Unit Age: Older compressors may require frequent filter changes due to wear and tear.

- Air Quality Conditions: Filters may need more frequent changes if operating in a dusty or high-moisture environment.

Why Regular Filter Changes Matter

- Ensures Consistent Airflow: Clean filters maintain proper air pressure and efficiency.

- Extends Compressor Lifespan: Prevents internal damage caused by dirt and oil buildup.

- Reduces Maintenance Costs: Regular filter changes help avoid costly repairs and downtime.

Keeping filter clean and replacing them on schedule is crucial for maintaining a reliable air supply in any shop or industrial setting.